When raising the roof considerably is not an option

It can be challenging to insulate historic buildings such as churches, museums, schools, Victorian houses, pubs and agricultural barns. This is because roof structures are variable and may require a creative approach to improve insulation. Boarded roofs are often used on these structures as they are tricky to insulate. The rafter space, where insulation is usually fitted, is separated from the roof above by an imposing board. Generally, this board is quite thick, taking up a substantial amount of space which could otherwise be used as part of the insulation profile. In older buildings with boarded roofs, rafters tend to be quite shallow. This makes it difficult to meet building regulation requirements with just traditional forms of insulation. When dealing with listed buildings, the amount of disturbance permitted to the structure of the roof may be limited, if allowed at all.

When the Museum of Gloucester needed a major refit, a compromise had to be made to be met between the roofers and the local building control. The necessity to improve the energy efficiency of the boarded roof, whilst maintaining a conscientious approach to the constructional constraints of the Grade II listed building were essential. With TLX’s technical team working in conjunction with Minster to establish the best solution for the contractor, the use of TLX Gold was agreed since it would provide excellent thermal improvement without considerably raising the roof height.

Using TLX Gold multi-foil insulation to maximise thermal efficiency

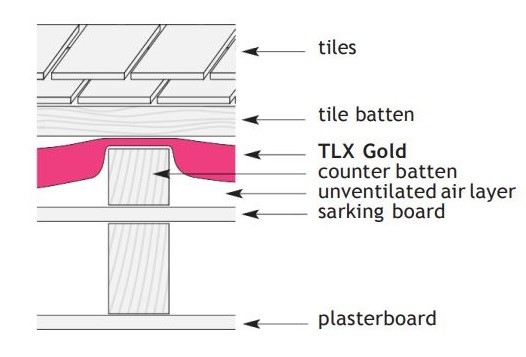

Although insulating a boarded roof can be met with difficulties, it is possible with the use of a multi-foil insulation. Firstly, 50mm counter-battens should be fitted above the boarding. Next, TLX Gold 2-in-1 insulating breathable membrane should be draped over the counter-battens and into the unventilated air space provided. This will achieve better thermal performance. The Museum of Gloucester project roofers welcomed the specification of TLX Gold as a single layer used in this way, providing a U value of 0.67 W/m2K. For comparison, a roof with no insulation usually has a U value of around 3.67 W/m2K. This proved a substantial thermal energy saving, especially for a listed building where building regulations don’t apply.

If a significant change to the roofline is permitted, a continuous sheet of PIR between the board and the counter-battens could reduce the U value much further. For example, to meet Building Regulations requirements of 0.18 W/m2K, 85mm of PIR can be used.